105 Tons Overhead Crane/Mobile Port Crane GHC105

105 Tons Overhead Crane/Mobile Port Crane GHC105

- +86 0513-80108718

- GENMA@RAINBOWCO.COM.CN

- 8613584712931

Overhead crane (mobile port crane)-a new type of port machinery that domestic old port machinery does not necessarily know!

The first crab in Asia

Genma is the first brand in Asia to launch overhead cranes (mobile port cranes), breaking the multi-year monopoly of European and American giants.

As of now, only less than 6 companies in the world provide this model!

V

-

-

Overhead crane (mobile port crane) PK traditional portal crane say No to low efficiency-true intelligence! 1 .Intelligent loading and unloading system, get rid of the technical dependence on the operator, easy to complete the intelligent setting of the loading and unloading path with 2 keys. The operating accuracy is ±5 cm. 2. Intelligent anti-sway technology, fast when the container is grabbed. Safe and stable 3. Intelligent grab technology, intelligent optimization of each grab action, maximum efficiency 4. Advanced product life cycle analysis system, predict and formulate maintenance plans And estimate the residual value of the product 5. Multiple machines are operated by a single person at the same time 6. Intelligent hydraulic accumulator, energy reuse

-

Long life cycle, high value of the second mobile phone and strong liquidity The trading of the second mobile phone of overhead crane (mobile port crane) is active, and the second mobile phone has high value and strong liquidity. -

-

Wide field of vision The Gemma overhead crane has two upper and lower cabs. 1. The upper driver’s cab is located in the middle of the tower column, in addition to controlling the single action and linkage of the crane’s lifting, luffing and slewing mechanisms, but also the telescopic action of the walking mechanism and outriggers, and the driver’s vision The open space improves the efficiency of loading and unloading and reduces the accident rate. 2. The lower cab is located on the turntable, which is mainly used for crane transfer transportation.

-

-

V

-

-

Compensation pulleys are installed The compensation pulleys are installed on the upper part of the Gemma overhead crane column to make the movement track of the heavy object level or approximately level during the luffing process, and reduce the lifting and lowering of the weight during the luffing process It consumes extra driving power.

-

-

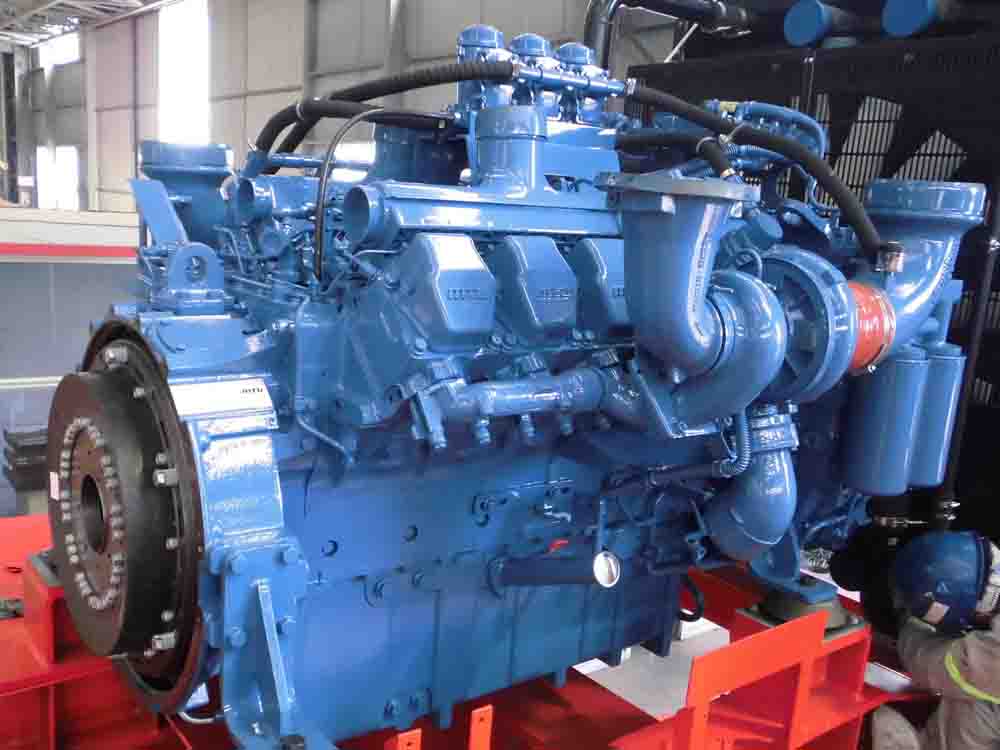

Dual power drive 1.Diesel engine drive 2. Shore power drive 3. Diesel engine & shore power dual drive switch

-

-

Stable and reliable work The Genma overhead crane can achieve light load high speed and heavy load low speed when it is hoisted, and it can automatically reduce or increase the rotation speed as the working range increases or decreases during rotation. , Work smoothly.

-

-

-

Overhead crane (mobile port crane) PK tire self-propelled crane Economy, small STS! The weight of Gema overhead crane It is only 30%-40% of the quayside container crane of the same level, and the price is only 50%-70% of the quayside container crane.

-

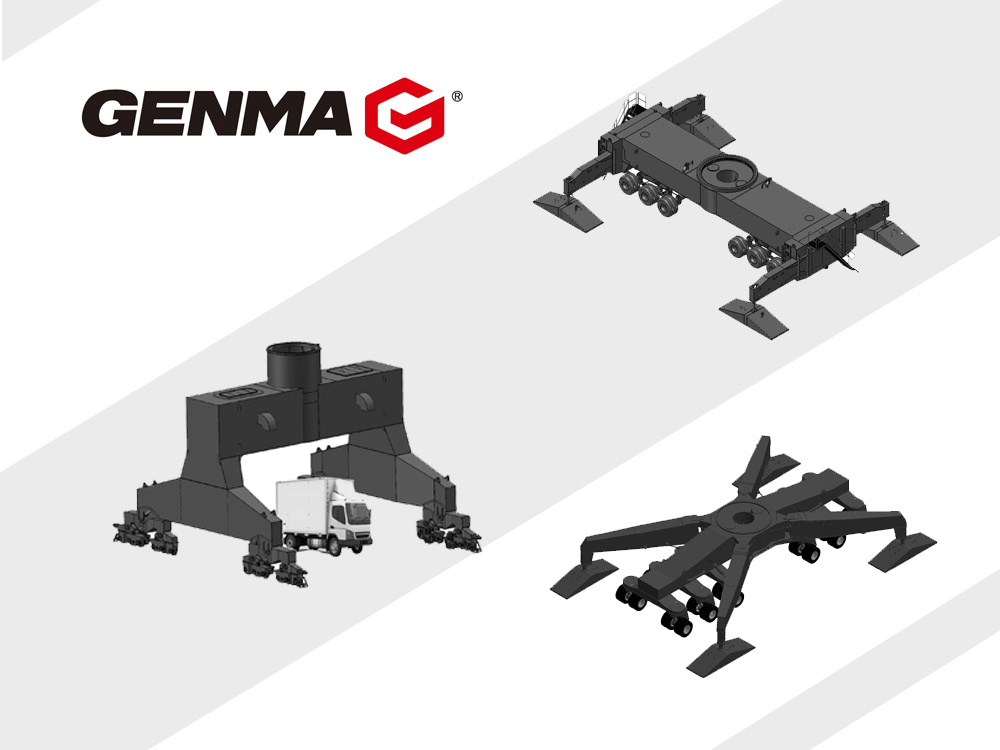

Highly flexible, one machine with multiple functions 1, 5 types of bases are available: tire type, track type, X bracket type, door Tire type, pedestal type 2, containers, bulk cargo, general cargo and a variety of goods can be applied 3, boom and tower can be used in a short time Put down or stand up inside. The transfer is convenient, and it can be operated at the front of the port or at the rear yard. Low wheel pressure, low requirements for wharf infrastructure, small wharves and old wharves can also be applied

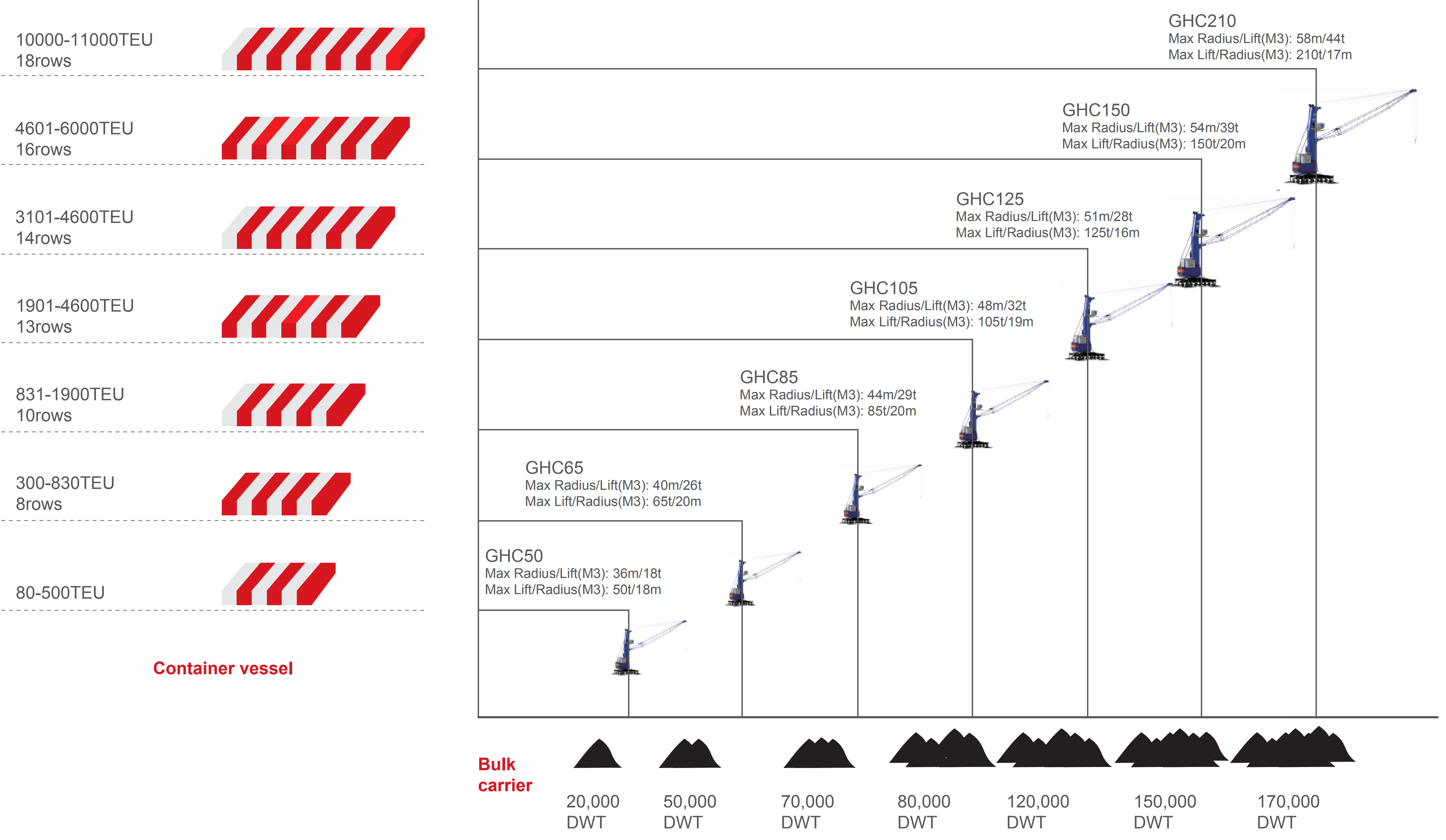

Gemma GHC series overhead crane (mobile port crane), the maximum lifting weight range is 50-210 tons, the maximum working radius range is 36-58 meters.

5 types of bases are available: tire type, track type, X bracket type, portal tire type, pedestal type.

Overhead craneGHC65

Overhead craneGHC85

Overhead craneGHC105

Overhead craneGHC125

Overhead craneGHC150

Overhead craneGHC210

-

-

V 3

V 3

More details

-

-

-

-

-

-

-

-

-

Model: GHC63

Model: GHC63

Base: Tyre type

Customer:Jiangsu Wenqiang Offshore

Quantity: 1

More details

-

-

-

V

V

-

-

-

Diesel fluid system

Diesel fluid system

The hoisting system, slewing system, and luffing system all benefit from the powerful hydraulic system to achieve precise control while meeting the needs of low energy consumption and easy maintenance.

-

-

-

5V

5V

-

-

-

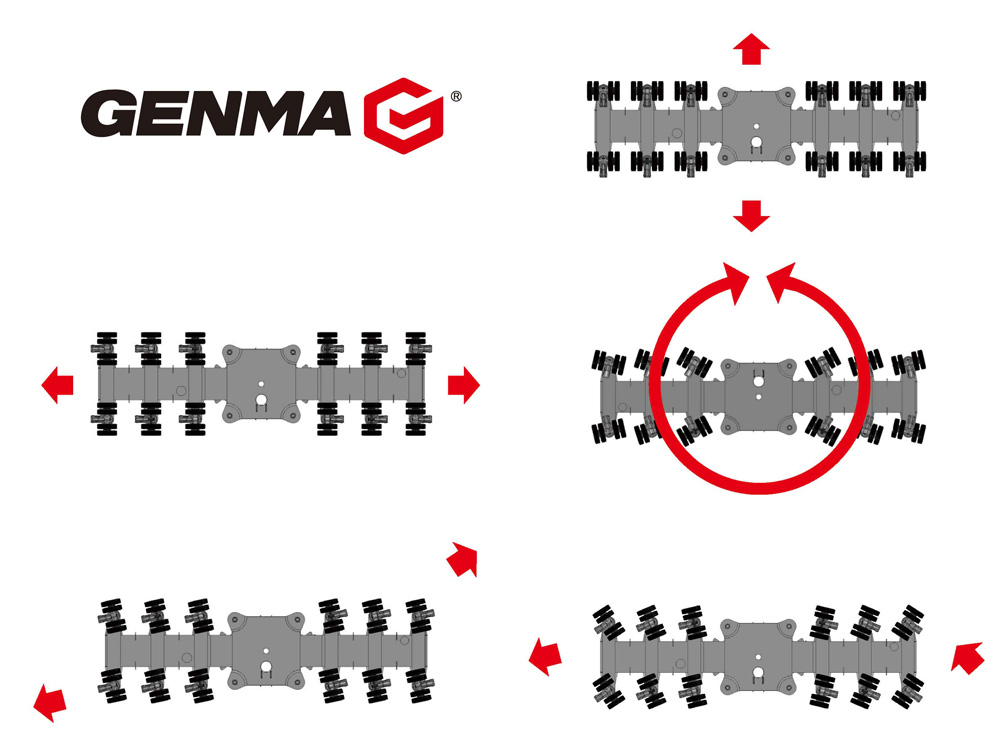

Handy and fast moving

Handy and fast moving

Handy and fast moving, meeting the port's multi-berth mobile operation requirements.

-

-

-

Electrical system

Electrical system

Genma only chooses top brand electronic components to ensure the performance of the whole machine and to facilitate the replacement and maintenance of after-sales spare parts.

-

-

-

Human-machine friendly design

Human-machine friendly design

The humanized design of the operating room has a wide field of vision and comfort. The most important thing is to facilitate driving and operation. Sound insulation and reflective glass in the cockpit further create a safe, undisturbed and efficient working environment.

-

-

-

V

V

-

-

-

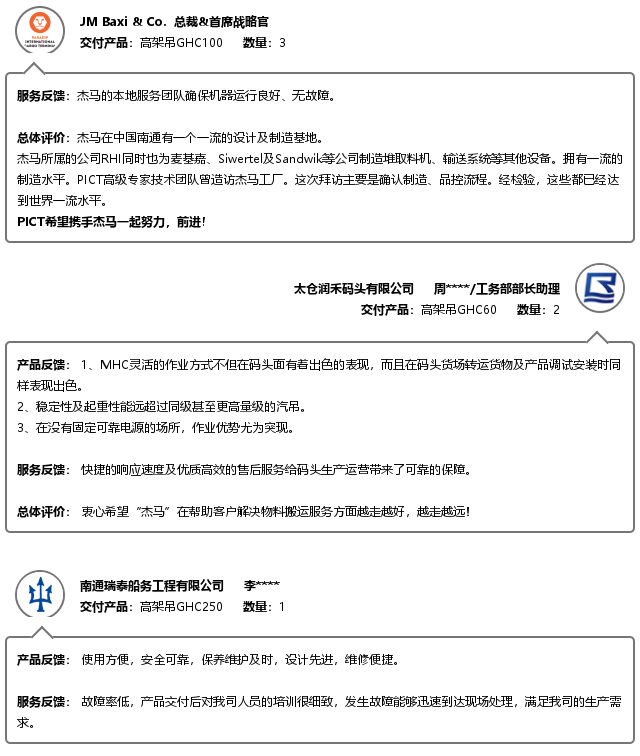

Localization service team, worry-free after-sales

Localization service team, worry-free after-sales

Gemma equips each project with an after-sales service team composed of experienced locals, quick response, no language and cultural barriers, and efficient communication. At the same time, the spare parts warehouse further guarantees the efficiency of after-sales service, allowing you to worry-free after-sales.

-

Rated efficiency& Working class

Main technical parameters

Working speed

Working range

Lifting height

Main dimensions

V

| Hook (heavy load conditions) | 105t | A3 |

|---|---|---|

| Container spreader (container working condition) | 51t | A7 |

| 4-rope grab (bulk cargo working condition) | 40t | A8 |

Main technical parameters

Working speed

| Lifting speed | 90 m/min |

|---|---|

| Maximum turning speed | 1.6 rpm |

| Maximum luffing speed | 85 m/min |

| Maximum walking speed | 5 km/h |

Working range

| Minimum amplitude | 11 meters |

|---|---|

| Maximum amplitude | 48 meters |

Lifting height

| Above the dock (under the maximum working range) | 30 meters |

|---|---|

| Below the dock | 15 meters |

Main dimensions

| Total crane width-in working condition | 14.9 m |

|---|---|

| - Walking state (at the narrowest width) | 8 meters |

| Total crane height-the highest point at the top of the tower | 34 meters |

V

| Wheel pressure | 6 tons |

|---|---|

| Under the maximum outrigger load, the outrigger coil pressure | 20.7 tons/m2 |

| The average pressure of the whole machine to the ground | 1.79 t/m2 |

Feedback form contact with us

Related Product

210 Tons Overhead Crane/Mobile Port Crane GHC210

Overhead crane (mobile port crane)-a new type of port machinery that domestic old port machinery ...

150 Tons Overhead Crane/mobile Harbor Crane GHC150

Overhead crane (mobile port crane)-a new type of port machinery that domestic old port machinery ...

125 Tons Overhead Crane/Mobile Port Crane GHC125

Overhead crane (mobile port crane)-a new type of port machinery that domestic old port machinery ...