Buried Scraper Ship Unloader

Buried Scraper Ship Unloader

- +86 0513-80108718

- GENMA@RAINBOWCO.COM.CN

- 8613584712931

The buried scraper ship unloader is mainly used for specialized grain terminals or fertilizer terminals, with high degree of automation and high efficiency.

It is suitable for ship types below 100,000DWT, and the unloading efficiency is from 600t/h to 1500t/h.

Buried scraper unloading is more and more favored by users due to its environmentally friendly and efficient unloading methods.

-

-

High efficiency

High efficiency

The ship unloading efficiency is high, reaching more than 70%.

The clearance workload is small.

-

-

-

Energy saving and environmental protection

Energy saving and environmental protection

The buried scraper ship unloader is compared with other ship unloaders

Lower energy consumption, unit energy consumption of unloading is lower than

0.4 kWh/t. At the same time, the material is being sealed

Convey in the machine tank without polluting the environment.

-

-

-

Flexible operation and high degree of automation

Flexible operation and high degree of automation

The operation of the equipment can be operated in the driver's cab,

Also equipped with remote operation box for remote operation

operate. Due to the uniqueness of the equipment,

High degree of automation, very little operation is required

You can operate the device by pressing the button

It has low requirements for drivers.

-

-

-

Low maintenance

Low maintenance

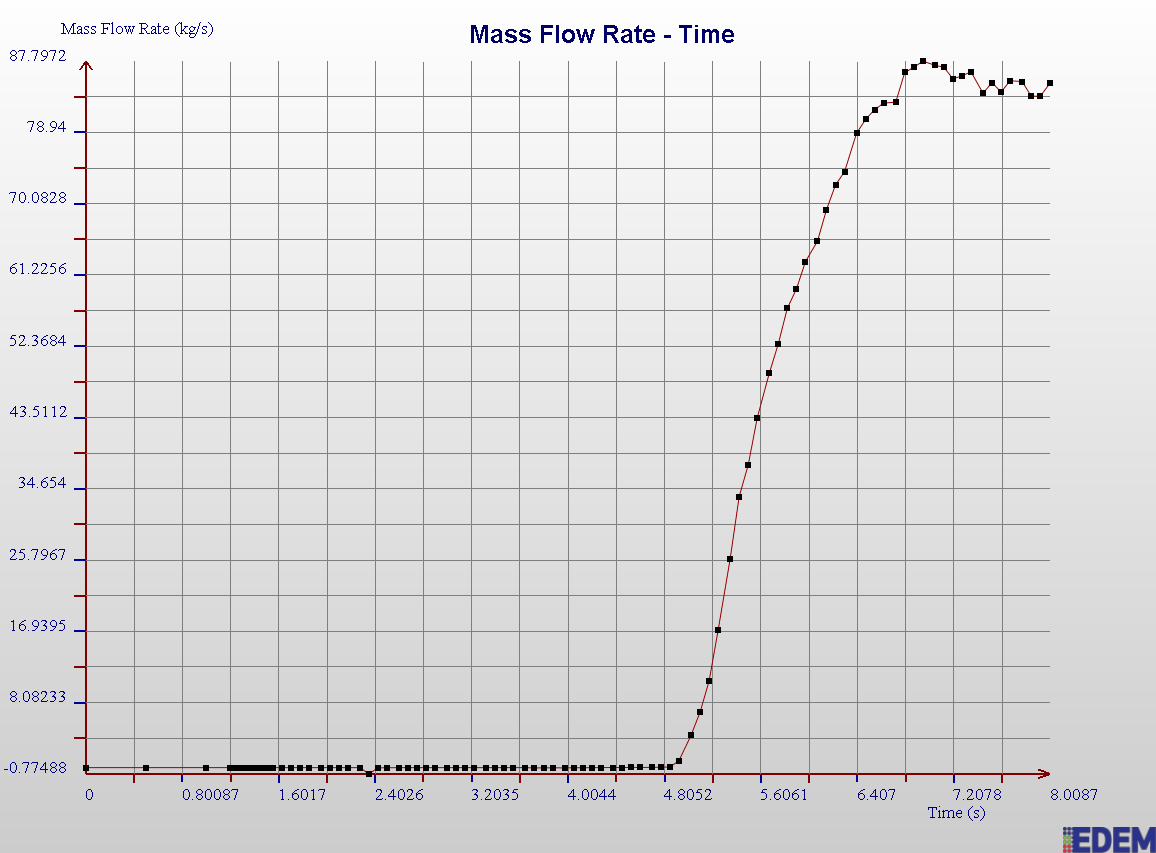

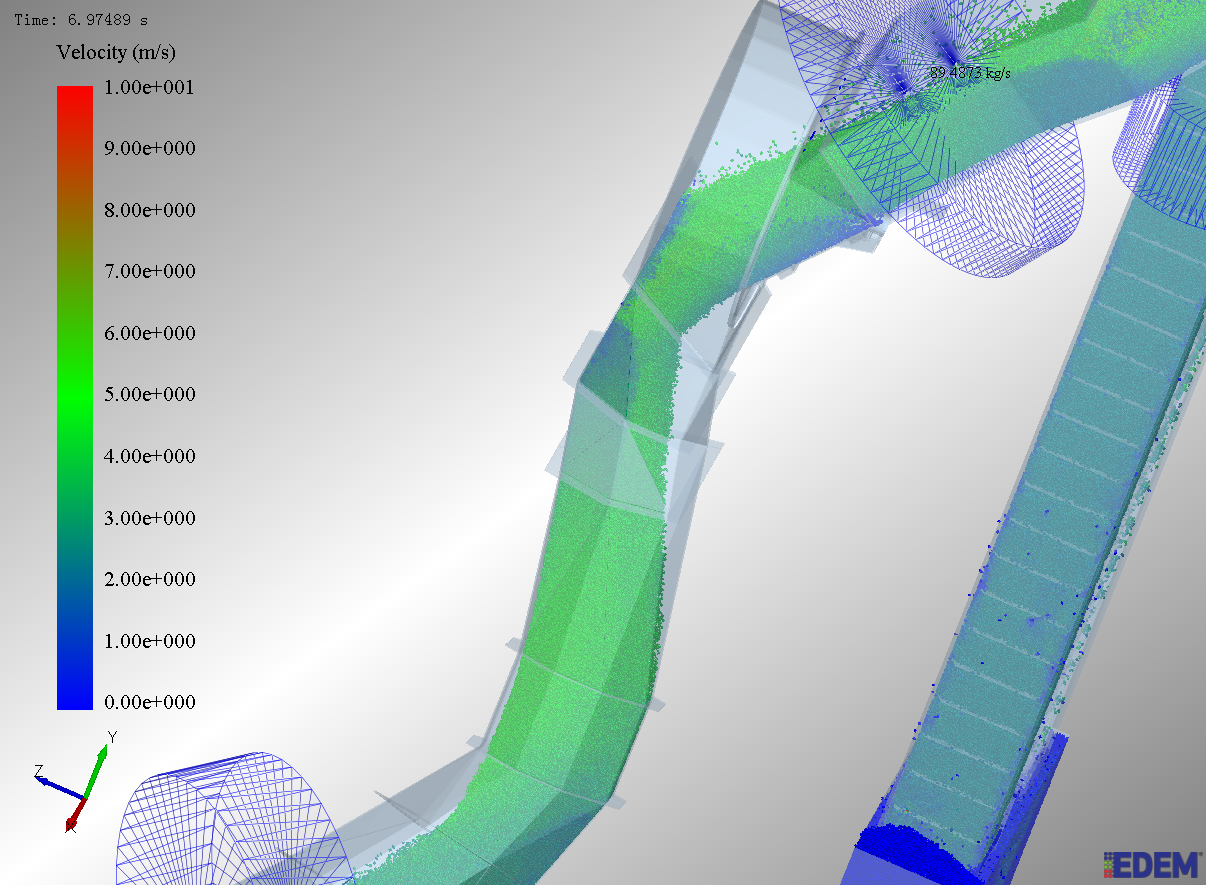

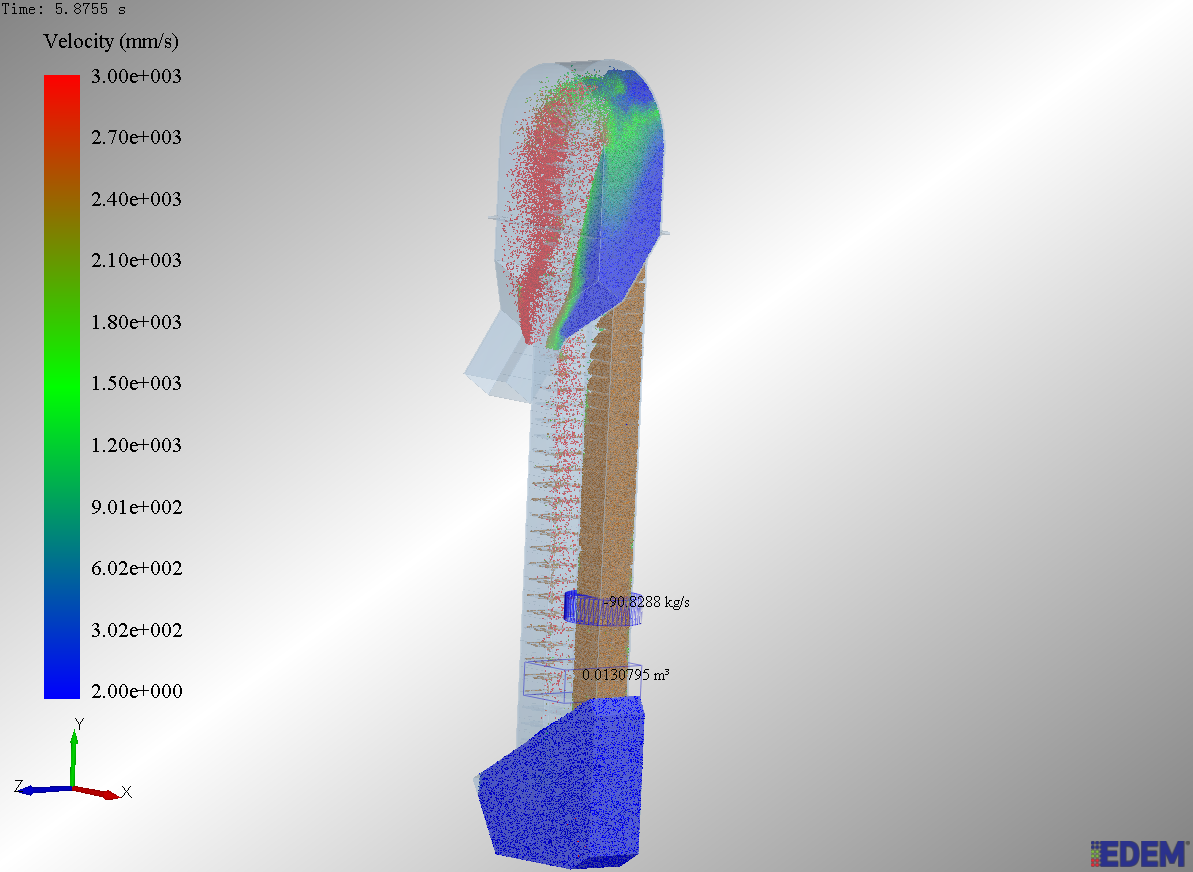

The chain is made of alloy steel, with long life and little equipment maintenance. EDEM discrete element analysis is used, and wear-resistant materials are used in the easy-to-wear locations to increase life and reduce maintenance.

-

-

-

Stable and reliable

Stable and reliable

Except for the clearance phase, the overall efficiency is stable. In order to improve the reliability and durability of the whole machine, the experimental equipment specially manufactured for the buried scraper ship unloader is used to collect the performance parameters and working status of the whole machine for unloading different materials. At the same time, the design adopts advanced discrete element analysis design to simulate the real unloading state, and further improve the stability and reliability of the whole machine.

-

Efficiency range: 600-1500 tons/hour

Suitable for ship types below 100,000 DWT

Suitable for ship types below 100,000 DWT

efficient

The ship unloading efficiency is high, reaching more than 70%.

Energy saving and environmental protection

The unit energy consumption is less than 0.4kwh/t. Airtight conveying environment protects materials without pollution.

Flexible operation and high degree of automation

Cab operation or remote operation is optional. Highly automated, simplified operation, operators can quickly start their posts.

Low maintenance

The alloy steel chain is used, and the wear-resistant material is used in the easy-to-wear position, which improves the life of the equipment and reduces the amount of maintenance.

The ship unloading efficiency is high, reaching more than 70%.

Energy saving and environmental protection

The unit energy consumption is less than 0.4kwh/t. Airtight conveying environment protects materials without pollution.

Flexible operation and high degree of automation

Cab operation or remote operation is optional. Highly automated, simplified operation, operators can quickly start their posts.

Low maintenance

The alloy steel chain is used, and the wear-resistant material is used in the easy-to-wear position, which improves the life of the equipment and reduces the amount of maintenance.

Feedback form contact with us

Related Product

Bridge Grab Ship Unloader

Gemma GGU bridge grab ship unloader is mainly used for bulk material unloading. Use the steel wir...

Chain Bucket Ship Unloader

Genma GBU series bucket chain ship unloader, a large mechanical ship unloader, suitable for unloadin...